This ISO 9001 GAP Analysis checklist will assist you to prepare for certification according to ISO 9001:2015 standard. Conduct an analysis to find out to what range your organisation already matches the ISO 9001 demands and where the focus of your implementation efforts should be. Use this knowledge to find out if the context of the company, planning, operations, quality control and product development is in order with the ISO standard. Download the ISO 9001:2015 checklist to create efficient on-site reports and immediately prescribe improving actions to the relevant people.

- Free Iso 9001 2015 Audit Checklist Excel Xls Example

- Free Iso 9001 2015 Audit Checklist Excel Xls

- Free Iso 9001 2015 Audit Checklist Excel Xls Format

- Audit Checklist Iso 9001

- Free Iso 9001 2015 Audit Checklist Excel Xls Example

ISO 9001:2015 specifies requirements for a quality management system when an organization: a) needs to demonstrate its ability to consistently provide products and services that meet customer and applicable statutory and regulatory requirements,. B) aims to enhance customer satisfaction through the effective application of the system. Iso 9001 2015 Audit Checklist Excel Xls – Database. When creating an official or organisation letter, discussion design as well as style is crucial to making an excellent impression. These layouts offer excellent instances of how you can structure such a letter, and also consist of sample material to work as an overview of design.

Say goodbye to paper checklists!

- Cut inspection time by 50%

- Uncover more issues and solve them 4x faster

- Select from over 5,000 expert-proofed templates

Digitalize this paper form now

Register for free on lumiformapp.com and conduct inspections via our mobile app

- Cut inspection time by 50%

- Uncover more issues and solve them 4x faster

- Select from over 4000 expert-proofed templates

ISO 9001:2015 GAP Analysis Checklist

Free Iso 9001 2015 Audit Checklist Excel Xls Example

Context of the Organization

Have all external and internal matters been identified that are important to the organisation's goals and the fulfilment of customer satisfaction and the strategic administration of the company?

Is your QMS implemented and does it include a description of the required processes and their sequence and interaction?

Have the criteria been determined to control these processes and their interaction?

Have the relevant needs and expectations of the parties involved been determined for the QMS?

Have all the responsibilities, methods, measurement procedures and related performance indicators necessary to ensure effective operation and control been put in place?

Has the scope of the QMS been defined taking into account all external and internal issues, the needs of the parties involved and the scope of the products and services?

Leadership

Have the demands for the QMS been integrated into the business processes and has the management supported process awareness?

Have the guidelines and objectives for the QMS, which are based on the strategic orientation of the organisation, been defined and communicated?

Has the company defined and communicated the responsibilities and authorities necessary for the effective operation of the QMS?

Does management feel responsible for the effectiveness of the QMS?

Have customer requirements and applicable legal and regulatory requirements been identified, met and communicated throughout the organization?

Are the risks and opportunities relevant to the QMS known?

Have the objectives been defined together with the appropriate departmental and personal levels of the company?

Planning

Is there a fixed method for determining the need for modifications to the QMS and checking their implementation?

Have the hazards and opportunities to be addressed to assure that the QMS can achieve its intended result(s) been identified?

Has the company planned measures to deal with these risks and opportunities and included them in the system processes?

Support

Is the monitoring or measurement to demonstrate the conformity of products and services related to specific requirements?

Has the company identified and provided the necessary resources to establish, implement, maintain and continuously improve the QMS (including human, environmental and infrastructure requirements)?

Has it been determined which information must be documented to comply with the required standards and which information is necessary for the effective implementation and operation of the QMS?

Has the company identified the knowledge required to operate its processes and to achieve conformity of products and services and introduced a learning process?

Has the company ensured that the employees who have an influence on the QMS have appropriate education, training or experience? Have measures been taken to ensure that these employees can acquire the necessary competence?

Operation

Is there a defined process to provide products and services that meet the requirements specified by the customer?

Are changes planned?

Are outsourced processes controlled and monitored?

Do you design and develop products or services?

Free Iso 9001 2015 Audit Checklist Excel Xls

Are the changes implemented in a controlled manner and steps are taken to mitigate adverse effects?

Is there a predefined process for reviewing information about products and services, inquiries, contracts or order processing and communicating with customers?

Free Iso 9001 2015 Audit Checklist Excel Xls Format

Is this verification carried out before the company undertakes to supply products and services?

Is it ensured that externally provided processes, products and services meet the specified requirements?

Have criteria been established for the evaluation, selection, monitoring of performance and re-evaluation of external providers?

Do the provide products and services manufactured under controlled conditions and include the following?

• the existence of documented information describing the characteristics of the products and services

• monitoring and analysis activities at proper stages to verify that the criteria for the control of processes and process outputs and the acceptance criteria for products and services are met

• monitoring and analysis activities at appropriate stages to confirm that standards for control of methods and process results, and approval criteria for products and services, have been reached

• the provision of recorded information defining the activities to be completed and the results to be reached

• the availability of reported information that defines the activities to be performed and the results to be achieved

• information on the competence of the persons performing the tasks

• the people implementing the tasks are qualified

Is the property of customers or external suppliers used in the performance of the product or service?

Does the company have adequate methods to assure traceability during the operational method?

Is there a demand for handling the products and services after delivery, such as guarantee, sustaining services, recycling or final disposal?

Are these established and managed?

Are any nonconforming method outputs arranged so as to avert their unintended use?

Performance Evaluation

Audit Checklist Iso 9001

Has it authenticated when the outcomes from observation and measurement shall be investigated and evaluated?

Have methods of observing customer perceptions of the provision of products and services been set?

Has an offer to perform management reviews been organised and performed?

Has the company set a process for an internal inspection of the QMS?

Has the company defined what needs to be observed and measured and the methods for monitoring, measurement, analysis and evaluation, to assure valid outcomes?

Has it fixed the demand or opportunities for developments within the QMS and how these will be put into management reviews?

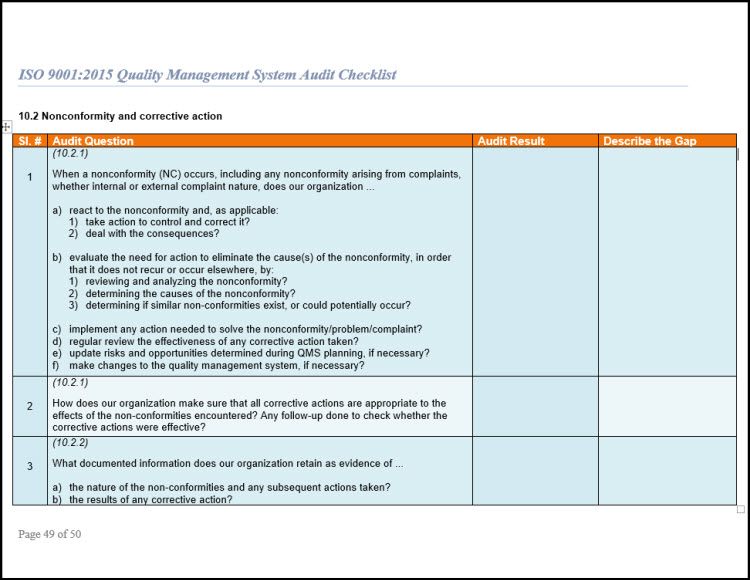

Improvement

Does the company operate proper processes for handling nonconformities and the associated improving actions?

Has the company decided on how it will discuss the necessity to continually develop the suitability, sufficiency, and effectiveness of the QMS?

Has the company determined and chose opportunities for development and implemented the required actions to meet customer demands and improve customer satisfaction?

Completion

Do you have any recommendations?

Name and signature of the inspector:

Please note that this checklist template is a hypothetical appuses-hero example and provides only standard information. The template does not aim to replace, among other things, workplace, health and safety advice, medical advice, diagnosis or treatment, or any other applicable law. You should seek your professional advice to determine whether the use of such a checklist is appropriate in your workplace or jurisdiction.

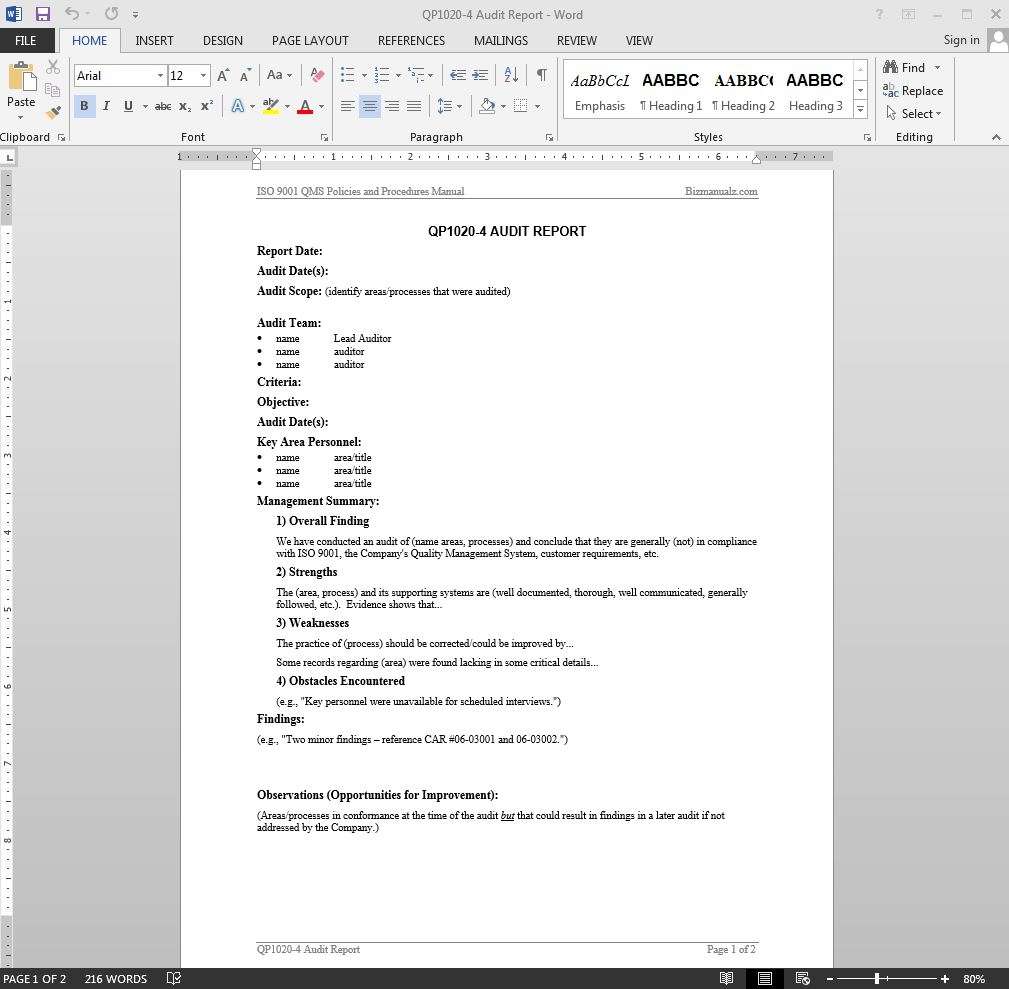

iso audit checklist template is a iso audit checklist template sample that gives infomration on iso audit checklist template doc. When designing iso audit checklist template, it is important to consider different iso audit checklist template format such as iso audit checklist template word, iso audit checklist template excel. You may add related information such as iso 9001 2015 checklist excel template, iso 9001 2015 internal audit checklist questions, free iso 9001 2015 audit checklist excel xls, iso 9001 2015 audit checklist doc.

iso audit checklist template

the purpose of this procedure is to define your organization’s responsibilities and activities in order to ensure that all inspection and test equipment used for product, service and process verification is controlled and calibrated against nationally traceable standards at specified intervals and that such devices are available to ensure continuity of measurement capability. this audit checklist may be used for element compliance audits and for process audits. then, simple reference is made to the procedures and work instructions from within the quality manual itself.

the purpose of this process is to define the activities required to ensure that product realization and planning encompasses the determination of product and process quality objectives, development of required processes, documentation and records. the purpose of this process is to ensure that all inspection and test equipment used for product and process verification is calibrated against nationally traceable standards at specified intervals and that such devices are available to ensure continuity of measurement capability. the purpose of this process is to moitor, measuring and take appropriate corrective action from customer complaints and feedback. but most importantly he is iso’s biggest fanboy and a true evangelist of the standards.

the occupational health and safety assessment series ohsas 18001:2007 audit checklist will help ensure your audits address the necessary requirements.internal audit template quality manual template procedures templates internal audit checklist- view sample. the audit checklist is just one of the many tools which are available from the auditor’s toolbox that help ensure your audits download iso audit checklists to assess your qms and prepare for certification. iso 9001:2015 internal audit checklist for regular self assessments. this iso 9001:2015 corrective action report template is a detailed set of steps which aim , iso 9001 2015 checklist excel template, iso 9001 2015 checklist excel template, iso 9001 2015 internal audit checklist questions, free iso 9001 2015 audit checklist excel xls, iso 9001 2015 audit checklist doc, iso 9001 2015 audit checklist doc

iso audit checklist template format

the occupational health and safety assessment series iso 18001:2007 audit checklist will help ensure your audits address the necessary requirements. it stands as a reference point before, during and after the audit process and if developed for a specific audit and used correctly will provide the following benefits: this audit checklist comprises tables of the certifiable (‘shall’) requirements, from section 4.0 to section 10.0 of iso 9001:2015, each required is phrased as a question. the self-assessment questions will help you to identify gaps between your existing environmental management system and the requirements of iso 14001:2015. the occupational health and safety assessment series iso 18001:2007 audit checklist will help ensure your audits address the necessary requirements.

it stands as a reference point before, during and after the audit process and if developed for a specific audit and used correctly will provide the following benefits: this audit checklist comprises tables of the certifiable (‘shall’) requirements, from section 4.0 to section 10.0 of iso 45001:2018, each required is phrased as a question. this audit checklist may be used for element compliance audits and for process audits. the application of our templates is scalable and generic; regardless of the size and type of organization.

pdf | iso 9001:2015 clause 9.2 internal audit the purpose of an internal audit is to systematic and independent assess the effectiveness of you can filter the internal audit checklist questions show those that apply to each 23, the process audit template replicates the turtle diagram (from the by developing the iso audit checklist and templates to align with the concepts, guidelines, and terminology given in iso 9000:2015, iso 9004:2018 and iso , iso 9001 2015 internal audit checklist for manufacturing company, integrated management system audit checklist xls, integrated management system audit checklist pdf, integrated management system audit checklist pdf, iso 9001 2015 templates free download, iso 9001 2015 checklist excel template, iso 9001 2015 internal audit checklist questions, free iso 9001 2015 audit checklist excel xls, iso 9001 2015 audit checklist doc, iso 9001 2015 internal audit checklist for manufacturing company, integrated management system audit checklist xls, integrated management system audit checklist pdf, iso 9001 2015 templates free download

iso audit checklist template download

an iso certification gives merit to companies, and protects consumers by ensuring that international safety, reliability, and quality standards are met. iso 9001 audit checklists can help assess the effectiveness of an organization’s quality management system (qms) and the achievement of iso 9001 certification requirements. get started with this iso 9001:2015 gap analysis and internal audit checklist built using iauditor – the world’s number #1 inspection software platform. use iauditor to assess your organization’s qms and take note of gaps and areas of improvement, and assign actions to appropriate departments.

use this to evaluate if the context of the organization, planning, operation, quality control, and product improvement complies with the iso standard. this iso 9001 internal audit checklist can be used as an internal audit to assess your organization’s qms and your readiness for third-party iso 9001:2015 certification. modify this template to suit your business requirements and the objectives of your qms and certification requirements. use iauditor to record and keep track of your internal audit scores. this iso 9001:2015 corrective action report template is a detailed set of steps which aim to eliminate process discrepancies, identify root cause/s or problems, and ultimately prevent their recurrence.